DUST: Smart Logistics Control

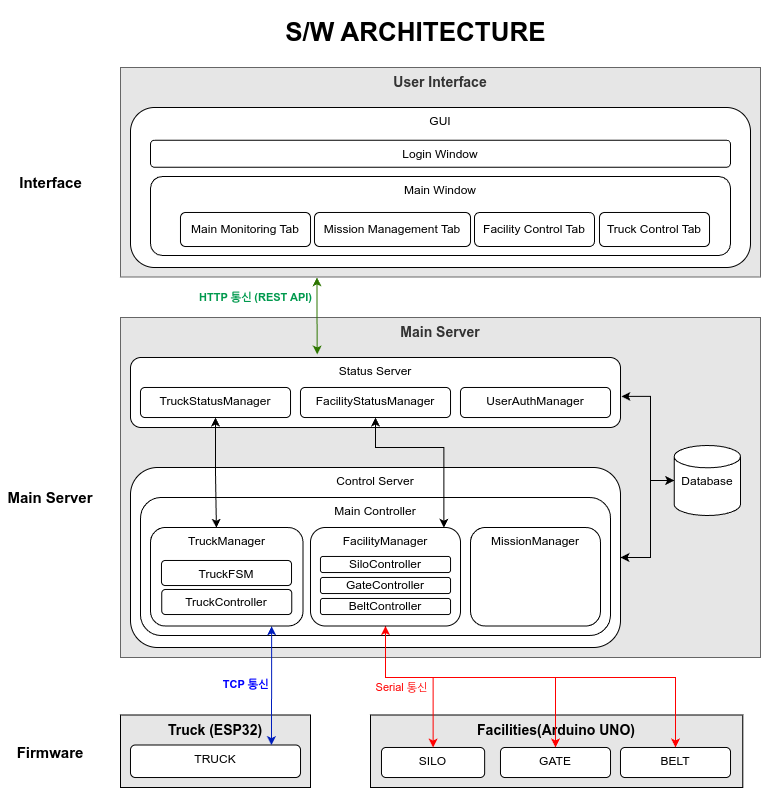

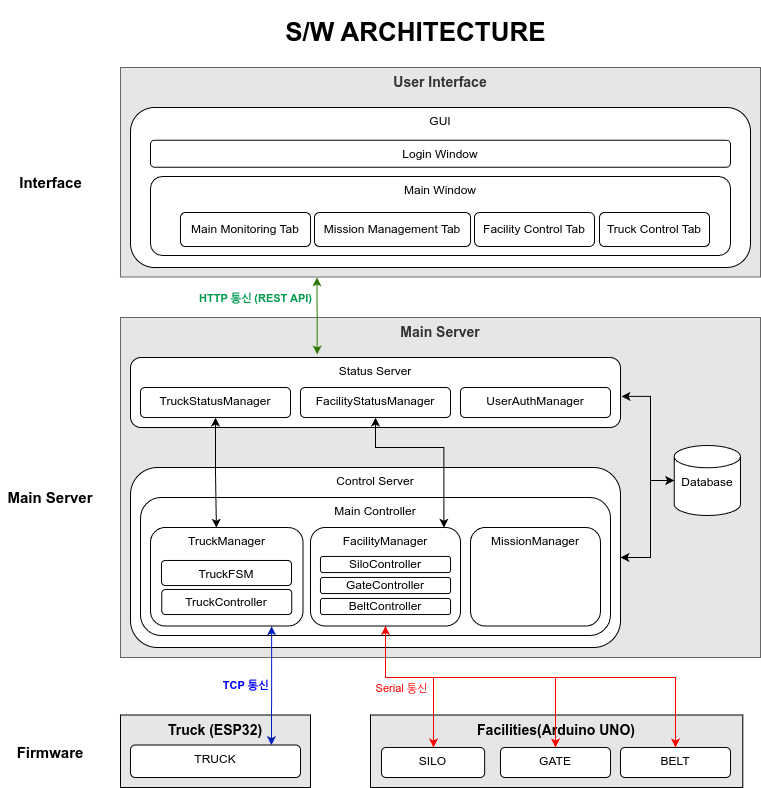

Dynamic Unified Smart Transport (DUST) is an IoT-based logistics platform orchestrating AGVs, conveyors, and gates. Features a custom binary protocol for high-speed, synchronized control.

Project Overview

DUST solves the challenge of coordinating heterogeneous logistics equipment. By integrating AGVs, automatic gates, and conveyor belts into a single control loop, it enables fully automated material transport with real-time status monitoring.

Key Engineering Contributions

Unified Control Architecture

Designed the overarching system architecture that unifies disparate hardware (mobile AGVs, static gates, conveyor belts) into a single synchronous control loop. Defined the master-slave state machine logic.

Custom Binary Protocol

Developed a lightweight custom TCP/IP binary protocol instead of standard JSON. This minimized overhead, reducing command latency by 3x and enabling sub-second synchronization between the central server and embedded controllers.

Central Control Server & Dashboard

Built the multi-threaded Central Control Server in Python. Developed the operator dashboard using PyQt, which provides a real-time "digital twin" view of the factory floor, showing active AGV paths and equipment states.

Core Technology

- Line Tracing & Navigation: PID control for line following combined with RFID tag detection for absolute localization.

- Communication: Socket-based TCP/IP architecture handling concurrent connections from multiple hardware nodes.

- Safety Interlocks: Hardware and software safeguards to prevent gate closure on AGVs or conveyor jams.

Tech Stack

Technical Challenges & Solutions

Problem: JSON parsing overhead caused delays in fast-moving AGV control

loops.

Solution: Designed a lightweight custom binary protocol, significantly

improving response times for stop/start commands.

Problem: RFID reading operations temporarily interfered with PWM motor

control signals.

Solution: Implemented a task scheduling strategy where PID updates are

briefly paused during critical RFID reads to maintain stability.